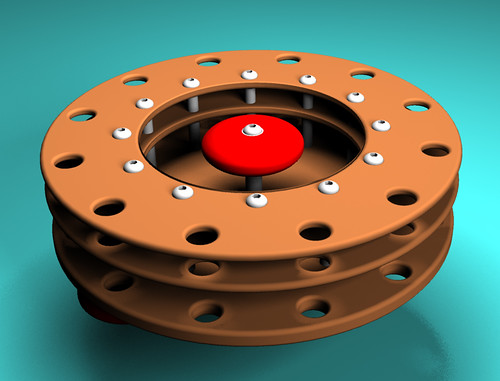

This winder design is based off of one that's apparently heavily used in Germany and most of Europe. I got my basic design from Erick, a fellow KAPer. This is my fourth or fifth revision of his design.

I want to be able to carry 500' of #200 and #100 Dacron line. Right now I carry two separate spools of 1000' of each. Since I never let out more than 500', I'm carrying unnecessary weight. Also, only one winder fits in my pack. I typically carry the other one in my hand (awkward, to say the least!) This lets me carry two weights of line in less space.

The center handle is an inline skate wheel. I took one from my scrap bin. With my fist wrapped around it, my entire hand-size is just over 5.5" in diameter. That's a 6.5" diameter ID on the side plates, so my hand should fit fine.

My earlier designs had winding handles on both sides, an idea Erick, among others, didn't much approve of. Since using an extension cord winder as my kite line winder for over a year now, I have to agree. As long as the center handle is placed pretty close to the mid-point of the winder's thickness so the forces all line up, you only really need a winding handle on one side.

In this drawing the winding handle is a second inline skate wheel (though it's hard to see, tucked on the bottom as it is.) In the final build I'm more likely to make a 1.5" diameter Delrin knob, and press the bearings in. It'll be more compact that way. The winding knob will be removable so the whole winder sits flat for packing into my backpack.

I already use the center of my current winder for storing my two 3m lengths of fuzzy tail. This cavity is actually larger, despite the handle in the middle, so it should still be able to fit the two lengths of tail, and might be able to hold my ground strap as well.

The side plates, as designed, are 1/4" and 1/2" plywood. If the outer 1/4" plywood is not sufficiently strong, I can swap it out for a 1/2" plate. Either that or reinforce it with fiberglass cloth. (I'd rather not go that route.) In any case the wood will be painted and sanded before assembly.

The spacing between the plates will be tuned by changing the lengths of the spacers on the twelve bolts. I only want 500' of each kind of line, so I can tune the length of the spacers to make things fit juuuust right. Right now my winders are 3.75" tall. I'm hoping to get this to be slightly flatter, but I won't know for sure until I wind on the line.

The holes around the periphery of the plates is so that the line can be clipped off at a given length using a carabiner. This is the technique I use on my current winder, and it works great. The holes also cut down on weight, though the amount is negligible, when you get right down to it.

The twelve bolts that hold the whole thing together are drawn as button head cap screws. I'll probably swap those out for flat head screws in the final build so the two side plates will be completely flat. I'm accident prone enough as it is. Anything that could be described as a "knuckle buster" will probably be closer to "finger remover" for me. Safety first!

I'm also going through my backpack to remove as much weight as I possibly can. One change I need to make, given that I'm doing more KAP hiking these days, is to get all my chargers and store them in a separate bag I can leave in the car. It really makes no sense to carry around a bunch of charging gear when the nearest source of power is back in my Jeep! There's a lot of room for improvements in this area. I can probably shave several pounds without much effort.

It'll be a good change. And cleaning out my pack will make hiking a lot easier.

Tom

No comments:

Post a Comment